After three rounds of tendering 43 ships were recruited for CLINSH. The fleet consists of 14 ships to be refitted with a greening technique and the other ships using a variety of techniques and fuels like GTL, LNG and HVO.

After some tendering effort also the companies for the online monitoring and the reference measurements were contracted. All shipowners were approached with a questionnaire in order to assess the situation on the ships. This was important because all ships are different in terms of the dimensions of the engine rooms and the installations that are onboard. After this assesment a visit to the ships was planned for the installation of the monitoring equipment. This turned out to be quite a challenge and asked a lot of flexibility. On some ships 2 or 3 engines were equipped with monitoring equipment. That was done when these engines were used in different patterns. Another point of attention turned out to be the fuel meters. The shipowners were responsible for a properly functioning fuel meter, that was precise enough and could provide the right output signal. In practice a lot of ships were not equipped with fuel meters that complied with these demands. In some cases, a good solution had to be developed.

Monitoring

On the ships that were refitted with financial aids of CLINSH the monitoring installation had to be installed again after the refit. Another issue could be that the monitoring installation on some ships stopped generating information. A number of reasons could be the cause of this. Especially in the first COVID period in the spring of 2020 it was impossible to fix this kind of issues on the ships.

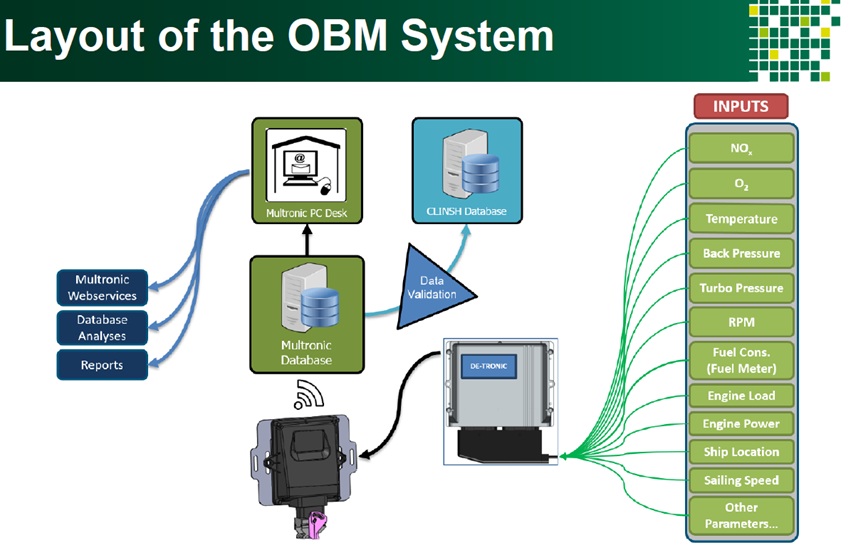

The continuous monitoring process is in itself quite straightforward. Once the monitoring installation is functional the processing unit that is installed on the ships collects the data and sent it with the telemetry module to the database. First the spikes and mistakes in the data readings were filtered out. This data is labelled as ‘checked’ data and delivered to the CLINSH database. The shipowners can access their own data with a personal inlog to a data dashboard.

During the monitoring reference measurements are carried out. One goal of the reference measurements is to check whether the continuous monitoring on the ships provides comparable NOx emission data and to do a validation. The second goal is to measure PM (Particulate Matter) of the ships.

Pratical issues

A practical issue that to light sometimes was the lack of availability of measuring openings in the exhaust of several ships, or in some cases they were too small. In those cases, new or bigger openings had to be made. This was sometimes complicated by all the isolation that is used on the exhaust systems and not all shipowners were very happy to remove this. The goal was to do 2 or 3 measurements on each ship. For the refit ships this is done in the period before the refit and after the refit. On two ships 4 measurement were done because of changes in the installation on board. COVID was a complication in this process, because during the spring of 2020 it was not possible to do any measurements on the ships at all. The measuring company had to be very flexible to achieve these results. For most of the ships it turned out that there was only a small

difference between the continuous monitoring data and the discontinuous measurements.

Currently all the validated data is being analysed and emission factors and emission scenarios are being developed. The end results will be presented at the CLINSH conference in 2021.